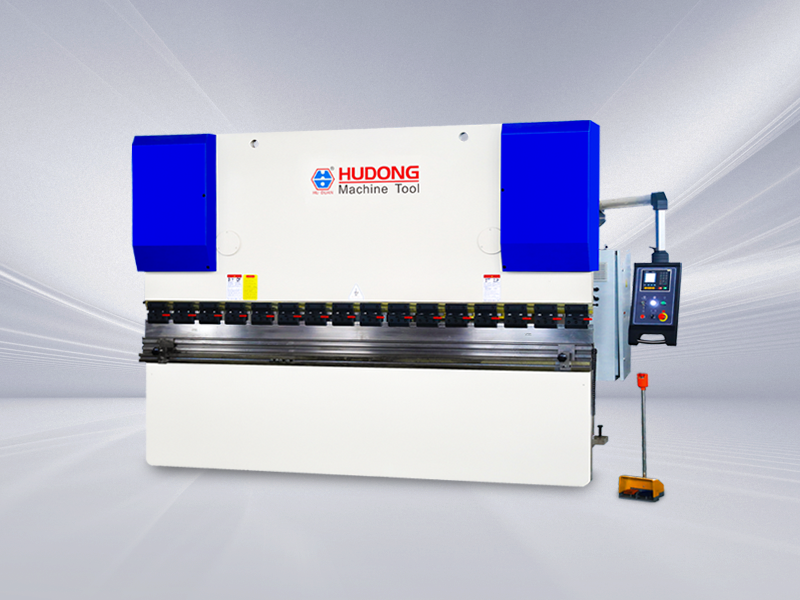

Hudong CNC1250-4000 Gantry Slotting Machine

- Commodity name: Hudong CNC1250-4000 Gantry Slotting Machine

- Product Description

-

Hudong 1250/4000 CNC Gantry Slotting Machine is full servo CNC gantry planer, which is with an advanced CNC system and a novel design. It has the characteristics of high processing accuracy, simple operation, no noise and no vibration. This equipment could machine V-groove, U-groove and other irregular groove in sheet metal parts, including stainless steel plate, aluminum plate, aluminum plastic plate, copper plate, iron plate, plywood, acrylic plate, and some other special plates. It is especially suitable for V-groove processing before bending of sheet metal parts.

Machine Parameters:

Model No. CNC1250/4000 Type Gantry Slotting Machine Certification ISO 9001:2000 Automation Automatic Suitable for Copper, Aluminum, Alloy, Carbon Steel, Stainless Steel Machine Weight 7.6ton Processing Length 4000mm Working Width 1250mm Minimum Edge Distance 8mm Machined Thickness 0.4-5mm Axes X. Y1. Y2 Z Maximum Speed of X-Axis 100m/min Y1 Axis Resolution Ratio 0.01mm Y2 Axis Resolution Ratio 0.01mm Z Axis Resolution Ratio 0.01mm X Axis Servo Motor 5.5kw Y1.Y2.Z Axis Servo Motor 1kw Hydraulic Station Oil Pump Motor 1.5kw Specification 5800x2250x1700mm Transport Package Container Trademark HUDUAN HS Code 8462490000 Main Configuration of Equipment

No. Machine Parts Brand No. Machine Parts Brand 1 Numerical Control System Easycat 10 Midget Relay Schneider 2 Blow the Solenoid Valve STNC 11 Flexible Power Cable Igus 3 Servo Drive Easycat 12 Proximity Switch Easycat 4 Servo Motor Easycat 13 Alloy Blade DASAN 5 Planet Reducer AMD 14 Linear Guide YINSW-HIWIN 6 PLC Easycat 15 High Precision Ball Screws HIWIN 7 Single / Bipolar Air Switch Schneider 16 Precision Gear Teeth AMD-JT 8 AC Contactor Schneider 17 Angular Contact Ball Bearing NSK 9 Circuit Breaker, Button Schneider 18 Double Film Coupling GND

EK15CNC Control System Easycat metal V-slot slotting machine CNC

system is matched in the slotting machine. The system allows users to

input processing data according to their own needs, and then control

the machine to automatically process products. The software has a lot

of knowledge about the operating habits of the operators, making the

system operation interface simple and human, fully understanding the

mechanical structure, making the machine run smoothly and efficiently,

reducing the failure rate, and creating higher value for customers.

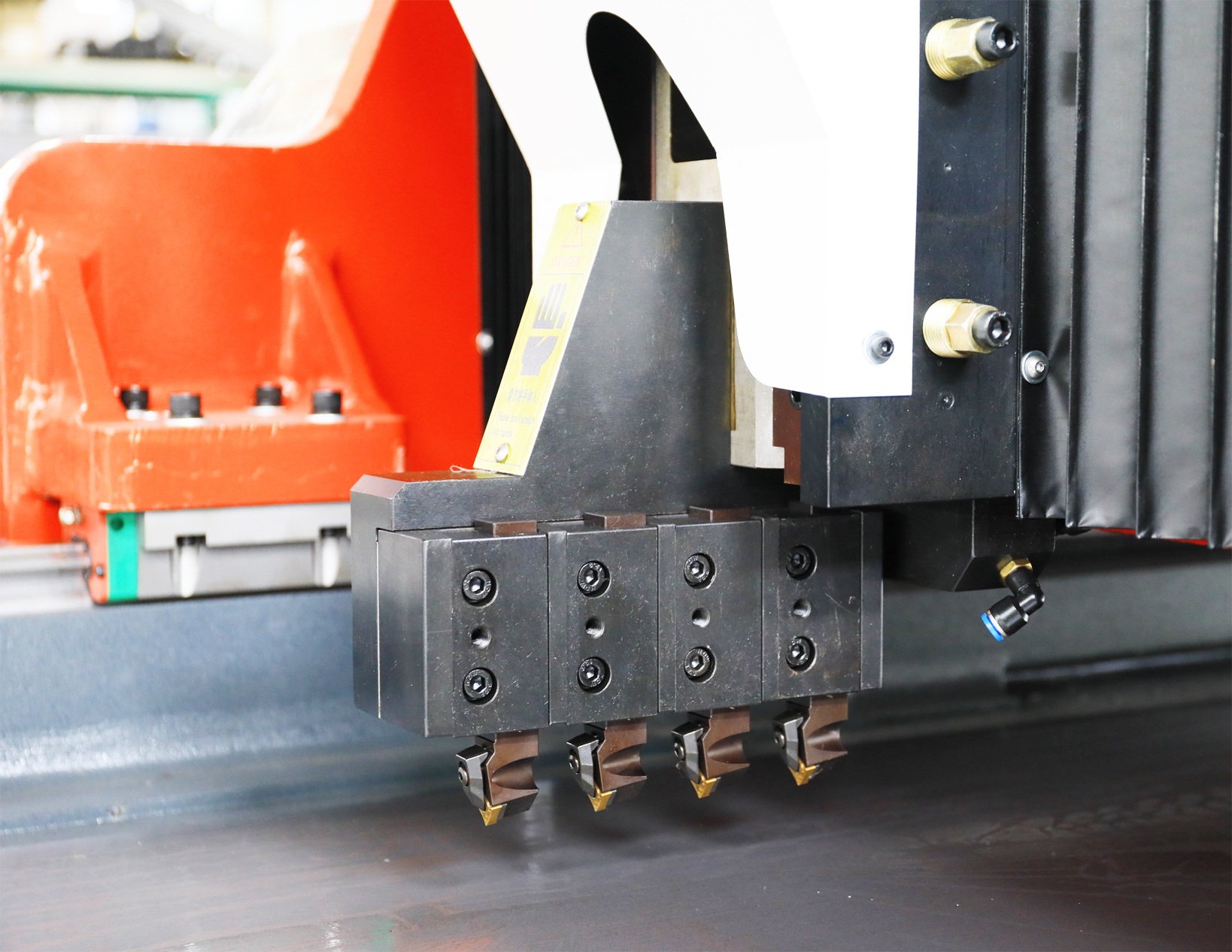

Slotting Surface

Micro cooling system(optional) will extend the tool life and reduce production cost.

Grooving with four blades will get better result and reduce the deformation.

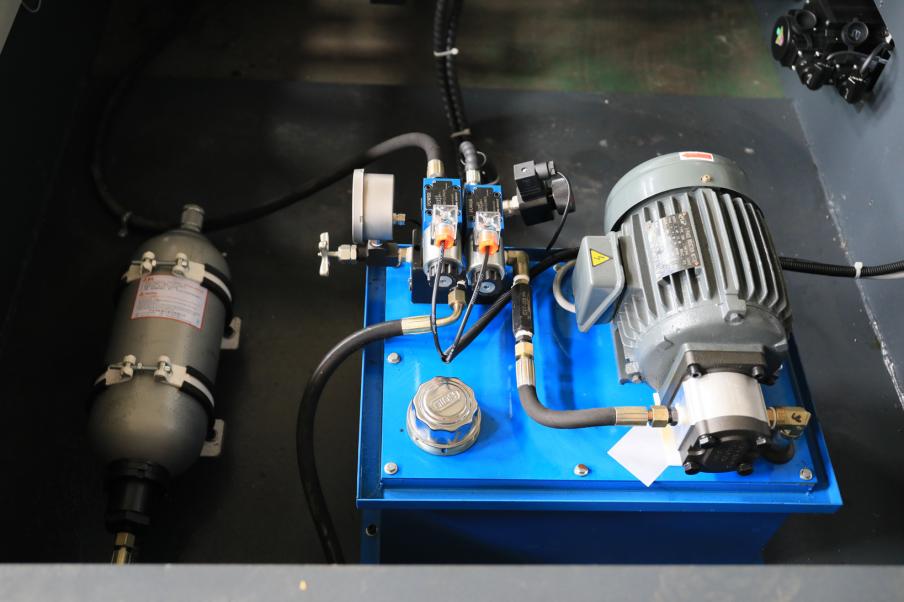

Hand pressure oil pump

Main servo motor

Guide rail

Pneumatic blowing system

Keywords