CNC bending machine: an excellent choice for modern manufacturing industry and bending machine power system

Release Time:

Sep 02,2024

Bending machine is a common machine in the processing industry. Bending machine is mainly used to shear metal materials. Generally, there are different types of machines, namely flat shearing, tumbling shearing and vibration shearing. Today, Wuxi Shenchong Bending Machine Factory will tell you in detail about the operation of this machine.

Bending machine is a common machine in the processing industry. Bending machine is mainly used to shear metal materials. Generally, there are different types of machines, namely flat shearing, tumbling shearing and vibration shearing. Today, Wuxi Shenchong Bending Machine Factory will tell you in detail about the operation of this machine.

Advantages of CNC Bending Machine

(1) High-precision performance:

CNC bending machine adopts advanced CNC technology, which can realize precise control of parameters such as bending angle and bending length, thereby ensuring high precision and consistency of processed products.

(2) Efficient production:

CNC bending machine is equipped with an automation system, which can realize automated production process and greatly improve production efficiency. Compared with traditional bending machine, CNC bending machine has faster production speed and can complete mass production tasks faster.

(3) Flexibility and diversification:

CNC bending machine can flexibly adjust processing parameters and processes according to different processing requirements to meet the processing requirements of different products. It can realize precise bending of various complex shapes of metal sheets and has strong adaptability and diversity.

(4) Reduce human errors:

The operation process of CNC bending machine is controlled by computer program, which reduces the interference and error of human operation and improves the consistency and quality stability of products.

Why does the manufacturing industry choose CNC bending machine?

(1) Improve production efficiency:

The automated production process of CNC bending machine can greatly improve production efficiency, reduce labor costs, and improve product processing accuracy and consistency.

(2) Reduce production costs:

The efficient production capacity and accurate processing quality of CNC bending machine can reduce production costs and improve the competitiveness of enterprises.

(3) Adapt to market demand:

With the continuous changes in market demand, the flexibility and diversity of CNC bending machine can meet the processing requirements of different products, making enterprises more competitive.

(4) Future development trend:

With the continuous advancement of science and technology, CNC technology will become more popular and mature. As one of the important applications of CNC technology in the field of metal processing, CNC bending machine has great development potential and market demand.

As an intelligent choice in modern manufacturing, CNC bending machines have many advantages such as high-precision performance, efficient production, flexibility and diversity. Choosing CNC bending machines can not only improve production efficiency and reduce production costs, but also adapt to the changing market demand, injecting new impetus and vitality into the development of enterprises. In the future, CNC bending machines will continue to play an important role and become one of the indispensable key equipment in modern manufacturing.

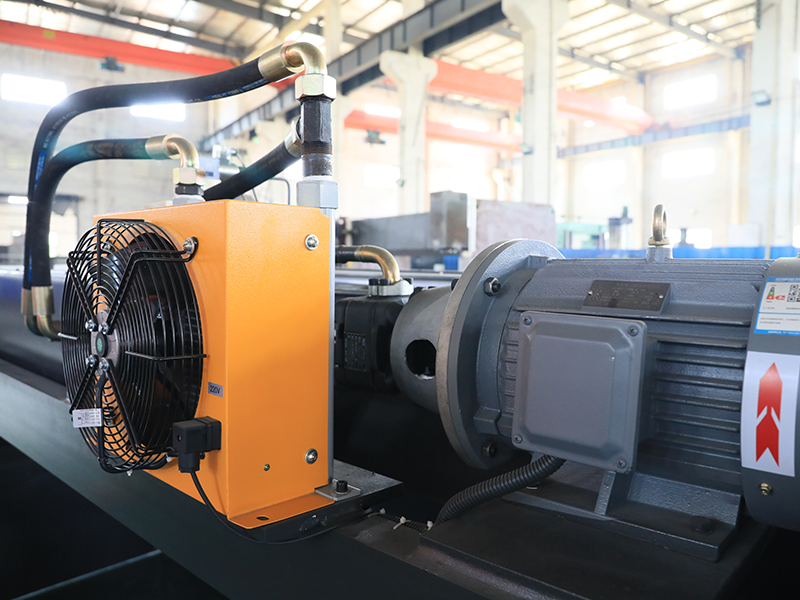

Bending machine power system

Like other industrial machinery, bending machines usually require specific electrical components and configurations to operate safely and efficiently. Choosing a suitable power cable for a bending machine requires considering multiple factors, among which current is one of the most critical factors. First, determine the maximum current of the bending machine during operation, which is usually determined by factors such as motor size, hydraulic system and other electrical components.

Power supply

Bending machines usually require three-phase power supply, and the specific voltage and current requirements vary depending on the size and capacity of the machine. Common voltages include 220V, 380V or 440V.

Circuit breakers

Circuit breakers are essential for protecting circuits from overloads and short circuits. Circuit breakers are installed on the power supply line and interrupt the current in the event of a fault. The ampere rating of the circuit breaker should match the maximum current requirement of the bending machine.

AC contactor

AC contactors are electromechanical switches used to control the power supply to the bending machine motor. They are usually controlled by the machine's control system (such as a PLC or manual switch). AC contactors provide a way to safely switch high-current motor circuits.

Emergency stop system

Press brakes are equipped with emergency stop buttons that can immediately cut off the power supply to the machine in an emergency. These buttons are connected to the machine's electrical system through safety relays or contactors to ensure fast and reliable shutdown.

Control system

Today's bending machines often use complex control systems, such as programmable logic controllers (PLCs), to regulate the operation of the machine. These control systems manage functions such as bending speed, backgauge positioning, and safety interlocks.

Limit switches

Limit switches are used to detect the position of the machine's moving parts, such as slides or backgauges. They provide feedback to the control system to ensure accurate positioning and prevent overtravel, thereby improving safety and precision.

Transformer

In some cases, a transformer may be needed to step down or step up the voltage to meet the requirements of the electrical components of the bending machine.

Grounding

Proper grounding is essential to ensure electrical safety and prevent electric shock. The bending machine should be grounded according to local electrical codes and regulations.

Safety features

In addition to the emergency stop button, the bending machine can also be equipped with other safety features such as light curtain protection, safety mats or two-hand operation controller to prevent accidents and injuries.